Chain slings provide excellent performance in harsh environments. When using chain for overhead lifting, an alloy grade, either grade 80 or 100, is recommended. We offer domestic & foreign chain in stock at locations across the US

A sling identification tag with the size, grade, rated capacity, and reach is required by OSHA regulation. Per ANSI/ASME B30.9. Some things you need to keep in mind:

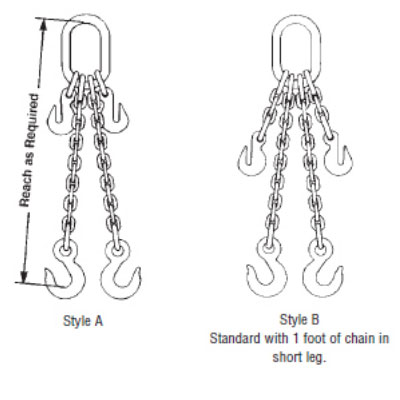

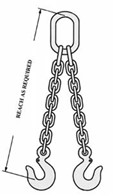

Types of Chain Slings

ALLOY CHAIN – the components used in welded or mechanical slings meet or exceed all existing OSHA, Federal NACM, ASTM and ISO chain specification requirements. Certificates for OSHA and internal record requirements are available upon request.

The WORKING LOAD LIMITS are based on a 4:1 design factor required by the International Standards Organization (ISO). Should an extreme load actually deform the chain, it will stretch (elongate) a minimum of 15% before breaking. An embossing of the chain link allow for easy identification of Alloy Chain.

While Grade 80 is the more commonly used, Grade 100 usage is increasing.

WELDED CHAIN SLINGS:

We maintain the specification of each welded sling on file under a unique registration serial number for inspection or should the chain require servicing. The rated capacity of a welded sling cannot be altered since its welded construction prevents on site tampering. Welded slings can be fabricated to your specific needs and are available with a variety of special end attachments.

MECHANICAL CHAIN SLINGS:

This flexible system saves on costly down time, since they can be repaired or altered on site. Components are manufactured under rigid quality control standards and meet or exceed the capacity of Grade 80 Chain.

Every component has forged marking indicating the alloy chain size to be used with it.

The following information is required to process an order or an inquiry:

• SIZE & GRADE: This is specified by the size of the material from which the chain is made and is dependent upon the working load limit required.

• REACH: This is the length, including attachments, measured from bearing point to bearing point.

• TYPE: Select and specify the proper type of sling from the list below. (ex. S – Single O – Oblong Link S – Sling Hook).

• ATTACHMENTS: Unless otherwise specified standard master links and hooks as given herein will be used. When other than standard attachments are required, we should be given a complete description or a drawing of the requested substitute.

WARNING

• ASME B30.9.1 requires all new components of alloy lifting chain assemblies to be proofloaded prior to their initial use.

• ASME B30.9.1 requires all repaired alloy lifting chain assemblies incorporating previously used components to be proofloaded prior to their initial use.

• When hot galvanized chain is specified, the recommended work load limits MUST be reduced.

• Please refer such inquiries to our nearest Branch Manager.

Proudly Distributing These Brands