Description

CAPACITY

VOLTAGE

- 115/230-1-60

- Reconnectible voltage

STANDARDS

- ANSI/NFPA 70, “National Electrical Code”

- ANSI/ASME B30.16, “Safety Standard—Overhead Hoists (Underhung)”

- ANSI/ASME HST—1M, “Performance Standard for Electric Chain Hoists”

BODY

- Compact die-cast aluminum

- Completely sealed body suitable for indoor, outdoor and harsh environments

- Easy maintenance hinged control panel for quick access

GEARS

- Heat treated helical and spur gears

- Submersed in an oil bath for quiet, smooth, cool operation

LOAD CHAIN

- Ultra-strong high-performance and corrosion resistant nickel-plated

- Grade 80 chain

- Made with unique technology to greatly increase resistance to fatigue and wear

CHAIN GUIDE

- Long-lasting, heavy cast iron construction

- Provides quiet and smooth guiding of the chain

- Easily replaced without disassembling the hoist

HOOKS

- Forged carbon steel opens gradually without fracturing under excessive loads

- Bottom hook swivels 360 degrees

- Top and bottom hooks have heavy-duty hook latch

CONTROLS

PUSH BUTTON STATION

- Impact-resistant plastic with molded strain relief to avoid damage from pulling on the push button cord

- Rated IP65

- 4 button (momentary contacts)

BRAKE

- Durable and reliable pull-rotor motor brake

- Has no brake coil to fail

MOTOR

- Totally enclosed fan cooled (TEFC)

- 60 minute, H4 rated for demanding applications

PROTECTION

- Long-life friction clutch protects hoist from damage

- Upper limit switch prevents overwinding/overlifting

TROLLEY FEATURES

- Drop stops

- Bumpers

- Side guide rollers

- Shafts fit wide flange range and have spacers for easy adjustments

- All steel wheels have sealed ball bearings and will fit a flat or tapered beam flange

OPTIONS

- Canvas, plastic or steel chain containers

- Longer lift or pendant lengths

- Longer shafts for wider beams

- Thermal overload protection

Electric Chain Hoists Catalog

Benefits/Features

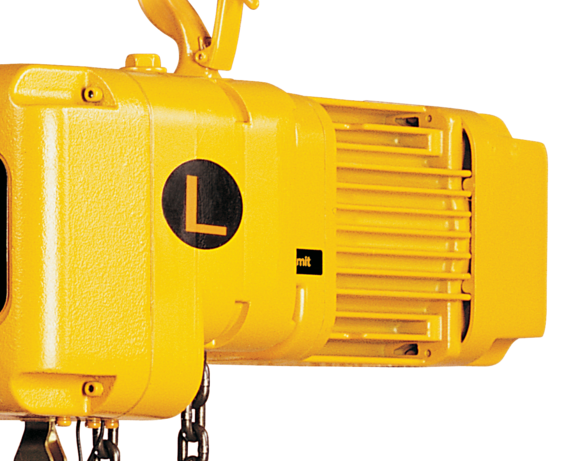

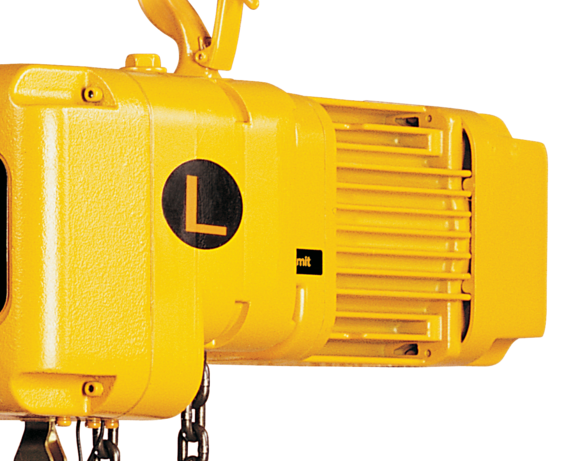

Extreme-Duty, Single-Phase Fan-Cooled Motor

The SNER electric hoist is equipped with a 60-minute H4-rated motor which is unmatched in a single-phase offering. Built for extremes, the SNER delivers proven performance in the most demanding applications.

PENDANT PLUG-IN CONNECTIONS

Saves valuable time on setup and maintenance. “Quick disconnect” replaces typical competitive hard-wired designs.

Self-Adjusting Maintenance-Free Brake

With no brake coil to fail or discs to replace, the electromagnetic pull rotor brake on the SNER is self-adjusting and virtually maintenance-free.

SEALED PROTECTION

Appropriate for both indoor and outdoor applications, including harsh environments. Gaskets throughout the trolley provide for an IP55 rating.

Oil Bath-Lubricated, Heat-Treated Gearing

Harrington’s own heat-treating process increases the overall hardness and strength of internal parts which run smoothly when immersed in an oil bath. This extends service life by reducing friction, vibration, and heat.